Clean Water Hydraulic Robots

Toward safe and clean robot systems

Introduction

Drive circuits

Robots

Fault detection and fail-safe control

Reference

Introduction

"Old Wisdom, New Insights" in Hydraulic Technology

We believe there is potential for hydraulic drives even in the relatively low-power range already well-covered by electric technologies. This potential lies in water hydraulics. Promising applications include field robots and robots related to food industries. As a driving technology capable of providing sufficient power for tasks while being harmless to both the environment and humans, few technologies are as attractive as water hydraulics.

However, as you may know, water hydraulics, despite being the oldest form of hydraulic technology, has historically been replaced by oil hydraulics due to the demands for high pressure and lubrication. Specifically, issues like "friction" and "cavitation" in the high-speed sliding parts of pumps and valves have hindered the widespread adoption of water hydraulics.

Air-Hydraulic Servo Booster (AHSB)

The AHSB is a water hydraulic servo technology we recently invented based on a traditional air-hydro booster. The air-hydro booster is a sort of hydrostatic transmission incorporating a pressure boosting mechanism that uses air pressure to drive a plunger, generating high water pressure. The ratio of the area of the pneumatic piston to that of the hydraulic plunger determines the air-to-hydro boost ratio. By employing feedback control, we made a "servo drive" capable of handling low-to-medium (up to 14 MPa) pressure hydraulic power without using a pump.

Since the boost ratio functions similarly to a gear ratio, it not only increases force but also achieves an appropriate reduction ratio, making it ideal for precise control of position and force. While pneumatic valves are required, the absence of hydraulic pumps and valves allows the system to bypass the typical technical challenges in water-hydraulics.

We are currently exploring several architectures of the system and plan to apply those with confirmed basic performance to robots such as manipulators, step by step.

A Literal "Feat of Separation"

This robot, with its drive source located externally, boasts an extremely simple structure and operates with agility (Imagine a commercially available high-pressure washer commonly found in many households). The robot, attached to the end of the hose, takes over heavy tasks. Beyond standard outdoor environments, it can perform reliably in muddy conditions where conventional electric robots struggle to enter, in hazardous areas harmful to humans, and in high-temperature or high-humidity environments. It can even be submerged underwater.

How Valuable Is Being Completely Harmless?

The hydraulic fluid is ordinary tap water. While prolonged use may cause water to seep out of the actuators, it is harmless and poses no risk of electric shock. Unlike oil, it is not sticky, does not emit unpleasant odors, and does not stain or pollute the environment. Even in the unlikely event of a system failure, the simple metallic construction ensures that repairs or replacements can be carried out easily.

Of course, not everything is perfect. A clear drawback of the AHSB is the size of its drive source. To generate the high pressure boost, it requires cylinders significantly larger than the actuators at the endpoint. As the number of axes increases, the size of the drive source grows proportionally. While weight reduction is possible, minimizing the physical footprint is fundamentally challenging. Furthermore, long pipe length adversely affects dynamic response.

Even so, we must ask whether there is a place for this clean robotic technology in the Anthropocene era — a world that increasingly values sustainability and environmental responsibility.

Why not join jus?

Driving circuit

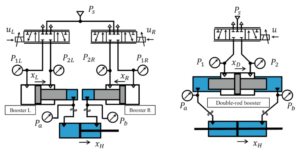

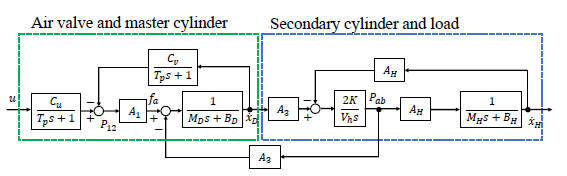

Single-rod and Double-rod AHSBs

Block diagram of AHSB

Robots

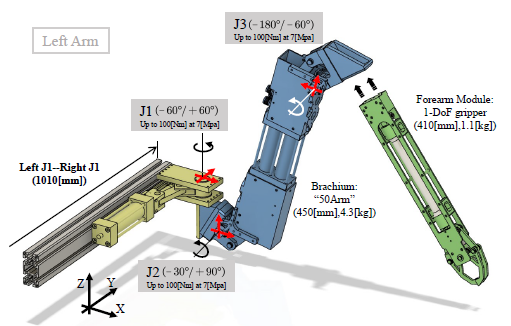

Suirikikun-II

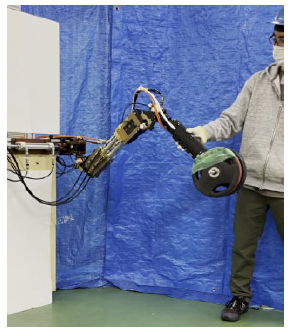

Suirikikun-II

Force control experiment on Suirikikun-II with a 15 kg payload

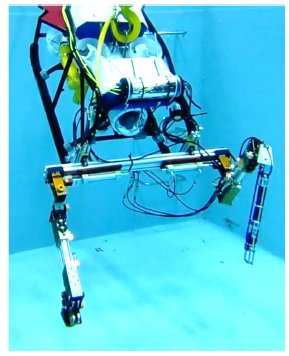

Dual-arm Suirikikun-II attached to ROV moving underwater

Fault detection and fail-safe control

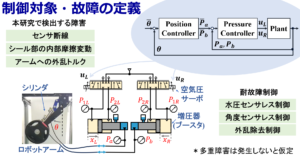

Definition of fails

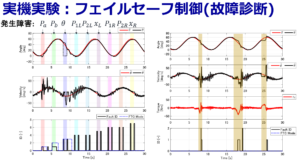

Experimental result of fail-safe control

Publication

- 渡邊悠希, 谷口友美, 玄相昊, 空気–液圧サーボ増圧器で駆動される水圧ロボットの状態推定とフェイルセーフ制御, 日本ロボット学会誌, 42 巻, 9 号, p. 928-931, 2024. https://doi.org/10.7210/jrsj.42.928

- S. Hyon, X. Han, Y. Watanabe and T. Hasegawa, "Development of a lightweight explosion-proof water hydraulic manipulator driven by air-operated HST with pressure booster," The 12th JFPS International Symposium on Fluid Power, P3-05, Hiroshima, Oct 24, 2024.

- Y. Watanabe and S. Hyon, "Experimental evaluation of Kalman-based fault diagnosis and fault-tolerant control on a water hydraulic robot arm," The 12th JFPS International Symposium on Fluid Power, P3-02, Hiroshima, Oct 24, 2024.

- 長谷川琢真, 玄相昊, 空液サーボ増圧器で駆動される水圧マニピュレータ試作機の動特性調査, 第42回日本ロボット学会学術講演会, 2024.

- 北澤拓人, 川戸咲智子, 玄相昊, 空気-液圧サーボ増圧器を用いた水圧ラバーマッスルの制御, 第42回日本ロボット学会学術講演会, 2024.

- Y. Watanabe and S. Hyon, "Fault detection and fault-tolerant control for water hydraulic robots driven by air-hydraulic servo booster," Proc. IEEE/SICE International Symposium on System Integration (SII2024), pp.1399-1404, 2024.

- 玄相昊, 韓笑, 安井一嘉, 渡邊悠希, 久木野詩織,"空液増圧器で駆動する防爆水圧マニピュレータ「水力君」の開発", 第41回日本ロボット学会学術講演会, 2023.

- 渡邊悠希, 谷口友美, 玄相昊,``空気-液圧サーボ増圧器を用いた水圧ロボットの状態推定とフェールセーフ制御'', 第41回日本ロボット学会学術講演会, 2023.

- 韓笑,安井一嘉,玄相昊,“水圧双腕マニピュレータの設計,”第23回計測自動制御学会システムインテグレーション部門講演会,pp 538-540, 2022.

- 渡邊悠希,玄相昊,“1本の光ファイバFBGセンサによるロボットアームの状態推定と制御,” 第23回計測自動制御学会システムインテグレーション部門講演会, p1447-1449, 2022.

- 玄相昊,久木野詩織, "空油増圧器で駆動される静油圧トランスミッションAHSTの解析", 第22回システムインテグレーション部門講演会, 2021.

- 谷口友美,玄相昊, "AHSBで駆動される水圧ロボットアームのセンサレス位置制御", 第22回システムインテグレーション部門講演会, 2021.

- 長良太暉,玄相昊, "水中ロボットのための回転軸と軸受の性能試験方法の検討", 第22回システムインテグレーション部門講演会, 2021.

- 安井一嘉,HanXiao,玄相昊, "軽量な水圧駆動水中ロボットアームの設計と基礎実験", 第22回システムインテグレーション部門講演会, 2021.

- S. Hyon and K. Akama, "Air-Hydraulic Servo Booster Toward Submersible Water-Driven Robots", IEEE Robotics and Automation Letters, vo.6, no.2, pp.1966-1972, 2021.

- 赤間一太, 谷口友美, 玄相昊, "水圧ロボットの空気-液圧サーボ増圧器による遠隔トルク制御", 日本ロボット学会誌, vol.39, no.4, 375-378, 2021.

- 赤間一太, 玄相昊, "水圧ロボットアームの空油圧サーボブースターによるインピーダンス制御", 第21回システムインテグレーション部門講演会, 2020, pp. 2932-2933.

- 赤間一太, 谷口友美, 玄相昊, "水圧ロボットアームの空油サーボブースターによる遠隔トルク制御", 第38回日本ロボット学会学術講演会, 2020.

- 玄相昊, 谷口友美, 大谷優, "空気圧で操作する水圧アクチュエータ", 2019年秋季フルードパワーシステム講演会講演論文集, pp.32-34, 2019.

2025/10/26